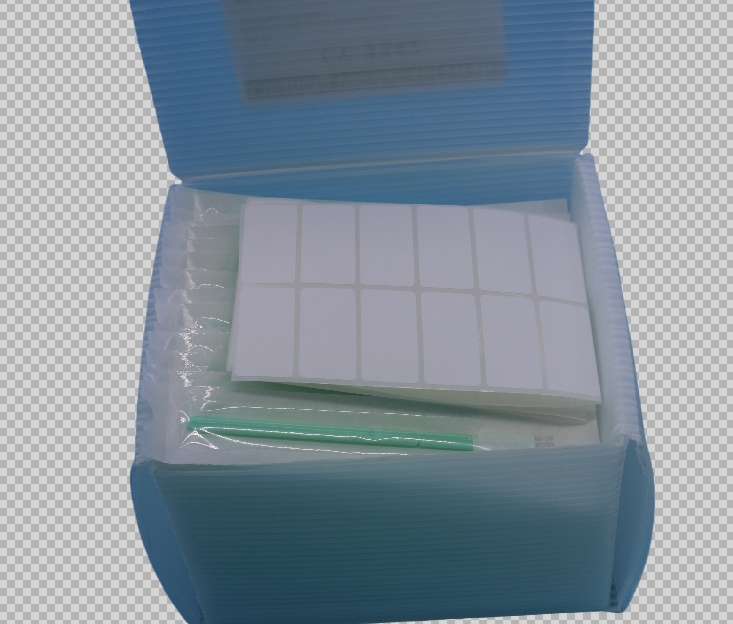

Low TOC iclean® Polyester Knit CY-714K Large Cleaning Validation Cleanroom Swab

433cleaning validation cleanroom swabs are used to determine the effectiveness of cleaning protocols as specified by the US FDA. HPLC/ UV-Vis Total O...

View detailsSearch the whole station Pandemic Supply

What is TOC Verification Sampling

TOC sampling verification is a process of evaluating the cleaning effect or whether the environment, samples, etc. meet relevant standards by collecting samples and testing the total organic carbon (TOC) content in cleaning verification and other scenarios. The following is a detailed introduction from the aspects of purpose, method, process, etc.:

Verification purpose 6

Ensure cleaning effect: In the pharmaceutical and food industries, production equipment needs to be cleaned after use. Through TOC sampling verification, it can be determined whether there are organic pollutants remaining on the surface of the equipment or in the cleaning fluid, confirm whether the cleaning procedure is effective, and whether the equipment can be cleaned to a level that meets production requirements to avoid residual substances from affecting the quality of subsequent products.

Ensure product quality and safety: Detect the TOC content of the environment or raw materials to prevent organic pollutants from exceeding the standard and introducing impurities, thereby ensuring the quality and safety of the final product and reducing the risks of product failure, deterioration, and harm to the health of users caused by pollution.

Meet regulatory and standard requirements: Relevant industry regulations and quality standards usually have strict regulations on production environment, equipment cleanliness, etc. TOC sampling verification is an important means for enterprises to meet regulatory compliance requirements and help enterprises pass inspections and audits by regulatory agencies.

Sampling method

Cotton swab wiping method: suitable for equipment that is easy to wipe and has a flat surface. Use a special TOC cleaning verification cotton swab to wipe the specified sampling area with a certain force and method (such as a straight line, S-shaped or spiral path) to adsorb the residual organic matter on the surface of the equipment onto the cotton swab, and then put the cotton swab into a specific sample bottle.

Eluent method: For equipment and pipelines that are not easy to wipe for sampling, the elution method is used. Rinse the equipment or pipeline with a certain amount of eluent (such as purified water, etc.), collect the eluent as a sample, and use it to determine the TOC content in it to infer the cleanliness of the internal surface of the equipment.

Verification process 1

Preparation stage: Personnel need to wear appropriate clean clothes, gloves and other personal protective equipment. Prepare sterile cotton swabs, TOC vials, markers, sampling labels and other tools and consumables that have a low TOC blank background and are suitable for TOC detection. According to the cleaning validation plan, determine the sampling area, number and location of sampling points. Usually, select the parts of the equipment surface that are difficult to clean and easy to accumulate residues.

Sampling operation: If the cotton swab wiping method is used, first use disposable dust-free paper or special cleaning cloth to perform preliminary cleaning near the sampling point to avoid cross contamination. Then use injection water to moisten the cotton swab head to ensure that the cotton swab is fully moistened but not excessively dripped, and then wipe the wet cotton swab evenly at the specified strength and speed to ensure that the entire sampling area is covered. If the elution method is used, the target part is eluted with the eluent in the specified amount and method, and the eluent is collected.

Sample processing and storage: If the same sampling point needs to be wiped multiple times, it may be necessary to gently stir and mix all the wiping cotton swabs in the container to obtain a representative sample. Immediately close the sampling container to ensure its sealing to prevent sample evaporation or contamination. If the sample needs to be sent for inspection within a certain period of time, it should be stored according to the conditions specified in the validation plan (such as refrigeration temperature) and sent to the laboratory for TOC analysis as soon as possible.

Laboratory analysis: According to the laboratory method, the sample may need to be filtered, diluted, extracted and other pre-treatment steps to meet the requirements of the TOC analyzer. Use a validated TOC analysis method to measure, record and calculate the TOC content of each sample. Compare the measurement results with the set cleaning limits to evaluate whether the cleaning effect meets the requirements.

What is TOC Verification Sampling Application areas

Pharmaceutical industry: used for production equipment cleaning verification, clean room environment monitoring, quality control of raw materials and packaging materials, etc., to ensure the sterility and pollution-free of the drug production process and ensure the quality of the drug.

Food and beverage industry: Cleaning verification of production equipment and processing environment, detection of the sanitary conditions of food contact surfaces, and quality inspection of raw materials, packaging materials, etc., to prevent organic contamination and ensure food safety.

Electronics industry: In the process of semiconductor manufacturing and electronic component production, TOC sampling verification is performed on production equipment, ultra-clean workshop environment, etc. to control organic pollutants and avoid affecting the performance of electronic products.

Water treatment industry: Monitor the TOC content in drinking water, industrial water, wastewater and other water bodies, evaluate water quality, and provide a basis for evaluating and optimizing the effect of water treatment processes.

cleaning validation cleanroom swabs are used to determine the effectiveness of cleaning protocols as specified by the US FDA. HPLC/ UV-Vis Total O...

View detailsIn industries where strict hygiene and quality control are of utmost importance, such as pharmaceuticals, food and beverage, and electronics, clean...

View detailsSwabbing is the preferred method to validate critical cleaning within pharmaceutical manufacturing environments. The 1993 FDA Guide to Inspections states that direct surface sampling (e.g., wi...

View detailsWe value your privacy We use cookies to enhance your browsing experience, serve personalized ads or content, and analyze our traffic. By clicking "Accept All", you consent to our use of cookies.

Our Privacy Policy